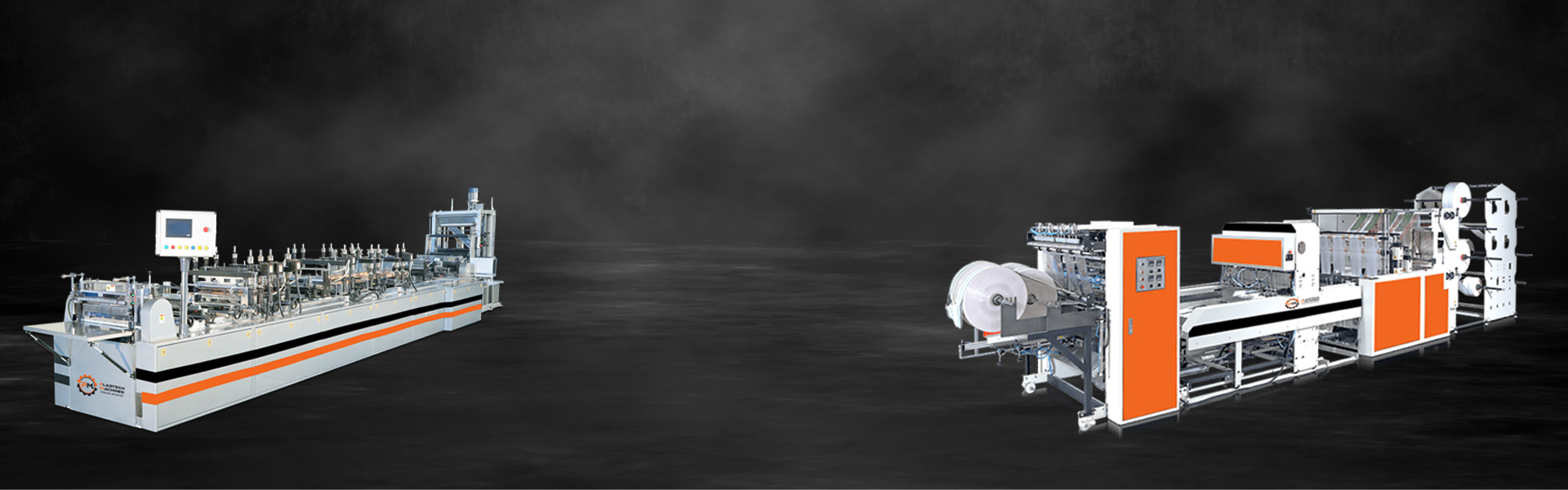

POUCH BAG MAKING MACHINE

POUCH BAG MAKING MACHINE

Request a QuoteMaterial Specification

|

TYPES OF MATERIAL |

Maximum (Micron) |

Minimum (Micron) |

|

PET PE |

200 |

30 |

|

CPP BOPP |

100 |

25 |

|

MET PET PE |

200 |

30 |

Technical Specifications

|

Sr. No. |

Name |

Remarks |

|

1 |

Film Working Width |

200-1000 mm |

|

2 |

Pouch Length |

100-1000 mm (500 mm above with skip) |

|

3 |

Pouch Width |

100-500 mm |

|

4 |

Mechanical Speed |

200 Cycles/Min. (Depends on Material, Size and Thickness) |

|

5 |

Maximum Roll Diameter |

600 mm |

|

6 |

Maximum Roll Weight |

200 Kg. |

|

7 |

Main Servo Motor & Drive |

1.5 KW (DELTA) |

|

8 |

Middle Servo Motor & Drive |

1.5 KW (DELTA) |

|

9 |

Transverse & Long seal station servo Drive & Motor |

1.0 KW (DELTA) |

|

10 |

Rear Index Servo Motor & Drive |

1.5 KW (DELTA) |

|

11 |

Nip Motor |

1.0 HP AC Motor (ROTOMOTIVE) |

|

12 |

Nip Motor Drive |

1.0 HP VFD (DELTA) |

|

13 |

Shearing Servo Motor & Drive |

0.5 KW (DELTA) |

|

14 |

Auto Stacker Motor |

0.5 HP AC Motor (ROTOMOTIVE) |

|

15 |

Auto Stacker Motor Drive |

0.5 HP VFD (DELTA) |

|

16 |

Human Machine Interface (HMI) |

7” Multi Color Touch Screen (DELTA) |

|

17 |

Program Logic Controller (PLC) |

28 I/O & 16 I/O Module (DELTA) |

|

18 |

Print Registration Photocell |

DATALOGIC |

|

19 |

Bearings |

SKF |

|

20 |

Pneumatic Component |

SMC make |

|

21 |

Static Unit |

4 No. Sockless Electrode |

|

22 |

Dimension of Machine |

L*W*H = 325*48*120 Inches |

|

23 |

Weight Of Machine |

2.5 Tons |

|

24 |

Machine Connected Load |

25.0 KW |

Standard scope of Supply

|

Sr. No. |

Standard scope of Supply |

|

1 |

Edge Guide Unit with Powder Brake controlling by Alteem system – 800 MM |

|

2 |

Film Folding device – 1000 MM |

|

3 |

Dancer Roll Assembly with NIP Roll Controlling By AC MOTOR |

|

4 |

Zip insert assembly with zip unwinder - 2 Set |

|

5 |

Long seal station 2 Set with 2 Section – Controlled by servo |

|

6 |

Stand up gusset Assembly |

|

7 |

Zip Sealing Tool – 2.75 * 3.0 * 2.75 MM – 2 Set |

|

8 |

Long Sealing Tool – 20 MM – 2 Set |

|

9 |

3 Roll Assembly – 3 SET |

|

10 |

Trimming Assembly with Suction |

|

11 |

Rear Index Assembly with Servo Controlling – Pneumatic – 2 Set |

|

12 |

Intermediate Dancer Assembly |

|

13 |

Transverse sealing station controlled by servo – 5 Set |

|

14 |

Transverse Sealing Station for Zip Squeezing |

|

15 |

Transverse Sealing Station – Metal to Metal |

|

16 |

Transverse Sealing Station – Rubber to Rubber |

|

17 |

Transverse Sealing Station – For Cooling |

|

18 |

Transverse Sealing Tool – 15 and 18 mm – 1 set |

|

19 |

Photocell Assembly – Datalogic |

|

20 |

V – Knotch Punch Assembly with Trolley - 1 Set |

|

21 |

Five side seal assembly |

|

22 |

Centre Slit Assembly |

|

23 |

Main Index Roll Assembly with Servo Controlling – Pneumatic |

|

24 |

Movable Shearing Assembly with Servo Controlling |

|

25 |

Auto Stacker Assembly |

|

26 |

Electrical Panel With 7” HMI |